In the competitive powder coating industry,

Powder Coating Line Suppliers are essential. Their equipment and services impact manufacturing processes. Let's explore key aspects about them.

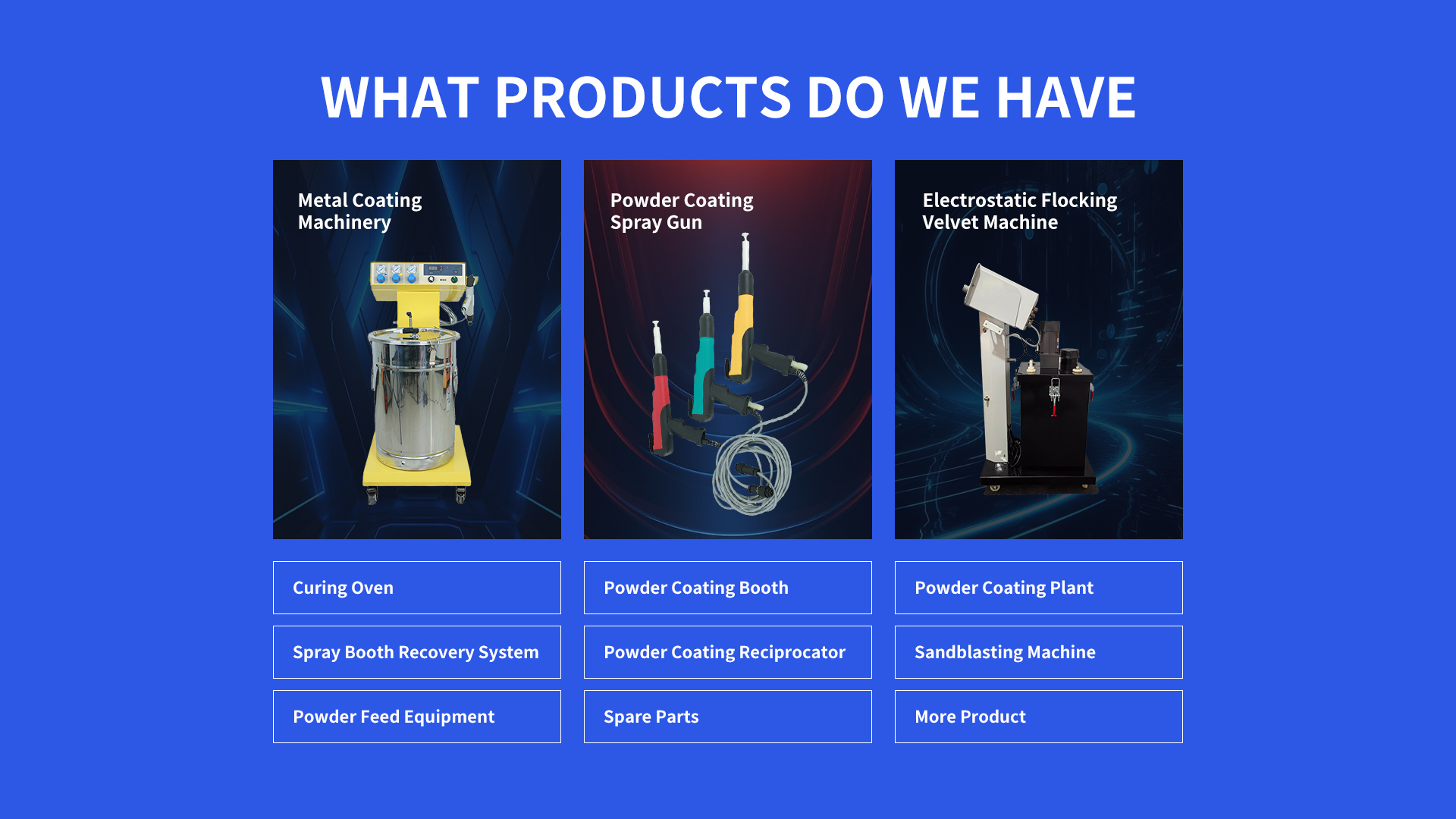

Powder Coating Line Suppliers offer a complete powder coating solution. A standard line has four main parts: a pre - treatment unit, powder - spraying booth, curing oven, and conveyor system.

The pre - treatment unit cleans workpieces, using methods like chemical degreasing, phosphating, and sandblasting.

The powder - spraying booth applies powder electrostatically, with adjustable spray gun settings.

The curing oven fuses the powder, having advanced temperature - control.

The conveyor system moves workpieces at adjustable speeds for smooth production.

These lines are used in multiple industries:

Automotive: For car bodies, bumpers, and wheels, providing a corrosion - resistant finish.

Furniture: Metal frames get powder - coated for a scratch - and rust - resistant look.

Construction: For components like window frames and handrails, improving corrosion resistance and appearance.

Prices vary:

Basic lines for small workshops start at $20,000.

Mid - range lines ($50,000 - $100,000) have semi - automatic spraying and better curing.

High - end, automated lines cost over $200,000 for large - scale production.

Before starting, ensure proper installation and calibration. Prime pre - treatment chemicals, adjust spraying parameters, set oven temperature and time, and operate the conveyor at a steady speed.

Consider production volume (high - volume needs high - end, automated lines), workpiece types (complex shapes need advanced spraying), and the supplier's reputation, after - sales service, and equipment quality.

Workers should wear safety gear. Ensure good ventilation in the spraying area and regularly inspect equipment for wear or malfunction.

The equipment has a modular structure for easy installation and maintenance, electrostatic spraying for less waste and better quality, precise oven temperature control, and a conveyor - based system for continuous production.

Q: Uneven powder coating thickness?

Q: Customization?

Q: Curing oven maintenance?

Q: Powder leakage in the spraying booth?

Q: Using different powder coatings?

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com